Umatshini wePlastiki oRecycling iGranulation luhlobo lwezixhobo ezisetyenziselwa ukucubungula inkunkuma okanye ukulahlwa kweplastiki kwiigranule zeplastiki ezinokuphinda zisetyenziswe. Inyibilikisa izinto zeplastiki ezisetyenzisiweyo ezifana ne-PE, i-PP, okanye i-PET kwaye iphinde ibunjwe kwakhona ibe yincinci, iipelisi ezifanayo ngokukhupha kunye nokusika.

Lo matshini udlala indima ephambili ekusetyenzisweni ngokutsha kweplastiki ngokuguqula iiplastiki ezilahliweyo zibe yimathiriyeli ekrwada yeemveliso ezintsha. Inceda ukunciphisa ungcoliseko lweplastiki, yehlisa iindleko zemveliso, kwaye ixhasa ukwenziwa okuzinzileyo kuwo wonke amashishini afana nokupakishwa, ukwakhiwa, kunye nempahla yabathengi.

Ukuqonda iimpawu, izinto eziluncedo kunye neengozi, kunye nokusetyenziswa okunokwenzeka koMshini wePlastiki wokuRecycling kwiGranulation kuya kukunceda wenze izigqibo ezingcono kwaye ukhethe igranulator efanelekileyo okanye indibaniselwano ukuhlangabezana neemfuno zakho zokuvelisa.

Qhubeka ufunda njengoko sinika iinkcukacha ezininzi ezahlukeneyo zoomatshini bePlastiki bokuRecycling beGranulation kwaye sinike isikhokelo esifutshane ekupheleni kwenqaku ukukhetha eyona granulator yeprojekthi yakho.

Iintlobo zeUmatshini wePlastiki oRecycling iGranulation

Oomatshini bale mihla bePlastiki bokuRecycling beGranulation bayilwe ngeenkqubo ezonga amandla, ulawulo oluzenzekelayo lobushushu, kunye nokucoca okuphambili ukuqinisekisa iigranuli ezikumgangatho ophezulu. Zisetyenziswa ngokubanzi kwizityalo zokuphinda zisetyenziswe, iifektri zeemveliso zeplastiki, kunye namaziko okulungisa okusingqongileyo ukuphatha uluhlu olubanzi lwenkunkuma yeplastiki, ukusuka kwifilimu kunye neebhotile ukuya kwiindawo ezifakwe inaliti.

Okulandelayo, siza kuxubusha ngokufutshane iindidi ezili-12 ezahlukeneyo zegranulator.

1. Ukurisayikilishwa komgca wegranulation wecompactor

I-Recycling Compactor Granulation Line yinkqubo epheleleyo esetyenziselwa ukusetyenzwa kwenkunkuma yeplastiki ekhaphukhaphu-efana neefilim, iingxowa ezilukiweyo, kunye nemathiriyeli enogwebu-kwiipeliti zeplastiki ezishinyeneyo. Idibanisa i-compaction, extrusion, filtration, kunye ne-pelletizing ibe yinkqubo enye eqhubekayo. I-compactor pre-compresss soft or bulky materials, okwenza kube lula ukuzondla kwi-extruder ngaphandle kwebhuloho okanye ukuvala.

Iingenelo

Ukondla okuLungileyo: I-compactor eyakhelwe-ngaphakathi i-pre-processed light and fluffy materials, ukuthintela imiqobo yokondla.

Inkqubo eDityanisiweyo: Idibanisa ukudibanisa, i-extrusion, i-filtration, kunye ne-pelletizing kumgca omnye oqhubekayo.

Indawo kunye nokugcinwa kwabasebenzi: Uyilo oludibeneyo kunye ne-automation ephezulu kunciphisa imfuno yomsebenzi wezandla kunye nendawo yefektri.

Ukuhambelana kweMathiriyeli ebanzi: Iphatha iiplastiki ezahlukeneyo ezithambileyo njengefilimu ye-PE/PP, iingxowa ezilukiweyo, kunye nemathiriyeli yogwebu.

Umgangatho wePellet ongaguqukiyo: Uvelisa iigranuli zeplastiki ezifanayo ezifanelekileyo ukuphinda zisetyenziswe kwimveliso.

Iingxaki

Ayizifanelanga iiPlastiki eziqinileyo: Iiplastiki ezishinyeneyo okanye eziqinileyo (umzekelo, iinxalenye ezibunjiweyo ngesitofu, iibhotile) zinokufuna abanye oomatshini.

Ukucoceka kwezinto ezifunekayo: Umswakama ophezulu okanye amanqanaba okungcola (njengokungcola okanye iphepha) kunokuchaphazela ukusebenza kunye nomgangatho wepellet.

Ukugcinwa rhoqo okufunekayo: I-compactor kunye neendawo zokucoca zifuna ukucocwa ngamaxesha athile ukuqinisekisa ukusebenza okuzinzile.

Usetyenziso

Ifilimu yezoLimo iRecycling: Yefilimu ye-PE mulch, ifilimu yegreenhouse, kunye nezinye iiplastiki zenkunkuma yasefama.

I-Post-Consumer Plastic Packaging: Ilungele ukusetyenzwa kweengxowa zokuthenga, ifilimu eyolula, iingxowa ze-courier, njl.

UkuBuyiselwa kweSilaphu seShishini: Irisayikilishe inkunkuma yemveliso evela kwifilim kunye nabavelisi beengxowa ezilukiweyo.

IziCwangciso zokuRecycling yePlastiki: Eyona ifanele izibonelelo zokuphatha umthamo omkhulu wenkunkuma yeplastiki ethambileyo.

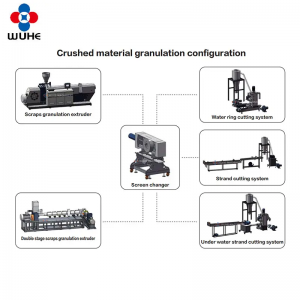

2.Umgca wegranulation yezinto ezityumkileyo

I-Crushed Material Granulation Line yinkqubo yohlaziyo yeplastiki eyenzelwe ukusetyenzwa kwenkunkuma eqinileyo yeplastiki esele icunyuziwe okanye yatyunyuzwa yangamaflakes. Oku kubandakanya izinto ezifana ne-HDPE, i-PP, i-PET, i-ABS, okanye i-PC esuka kwiibhotile, izitya, kunye ne-industrial scrap. Umgca ubandakanya inkqubo yokutya, enye okanye i-twin-screw extruder, iyunithi yokucoca, inkqubo ye-pelletizing, kunye necandelo lokupholisa / ukomisa.

Iingenelo

Ukutya okuthe ngqo kweZincedisi ezityumkileyo: Akukho mfuneko yokulungiswa kwangaphambili; zilungele iiplastiki eziqinileyo njengeebhotile, izikhongozeli, kunye neendawo zokutofa.

Imveliso eZinzile: Isebenza kakuhle kunye nezinto ezifanayo, ezixineneyo, zibonelela nge-extrusion ehambelanayo kunye nomgangatho wepellet.

Ukusebenza okuphezulu: uyilo oluqinileyo lwe-screw kunye nenkqubo esebenzayo yokususa igesi iphucula ukunyibilika kunye nokunciphisa imiba yokufuma.

I-Flexible Configuration: Inokuxhotyiswa nge-extruders enye okanye i-twin-stage, i-ring-ring okanye i-strand pelletizers ngokusekelwe kuhlobo lwezinto eziphathekayo.

Ilungile kwiRegrind ecocekileyo: Isebenza ngakumbi xa kusetyenzwa ecocekileyo, iiflakes zeplastiki ezicwangcisiweyo ukusuka kwimigca yokuhlamba.

Iingxaki

Ayilunganga kwiiPlastiki ezithambileyo okanye eziFluffy: Izinto ezikhanyayo ezifana neefilimu okanye amagwebu zinokubangela ukungazinzi kokutya okanye ukuvala ibhulorho.

Ifuna ukuhlanjwa kwangaphambili: Izinto ezimdaka okanye ezosulelekileyo ezityumkileyo zifuna ukucocwa ngokucokisekileyo phambi kokuba kuhlanjwe igranulation.

Ngaphantsi Ukufaneleka kwiiPlastiki ezixutywe: Izinto eziphathekayo zichaphazela umgangatho wepellet; Iintlobo zepolymer ezixubileyo zinokufuna ukudibanisa okanye ukwahlula.

Usetyenziso

I-Rigid Plastic Recycling: Kwiibhotile ze-HDPE/PP, izikhongozeli zeshampoo, imigqomo yokucoca, njl.

I-Post-Industrial Plastic Scrap: Ifanelekile intsalela etyumkileyo ukusuka kwi-injection yokubumba, i-extrusion, okanye i-blow molding.

IiFlakes ezihlanjiweyo ezivela kwiiNdlela zokuSebenza kwakhona: Isebenza kakuhle kunye ne-PET ecocekileyo, i-PE, okanye i-PP flakes kwiinkqubo zokuhlamba iibhotile.

Abavelisi bePlastiki yePellet: Ilungele abavelisi abaguqula i-regrind ecocekileyo ibe yipellets ephinda isetyenziswe ukuze ifakwe inaliti okanye i-extrusion.

3. Ibhegi yelaphu elukiweyo iphinda isetyenziswe kwipelletizing line

Ibhegi eLukiweyo iRecycling Pelletizing Line yinkqubo ekhethekileyo yokurisayikilisha eyilelwe ukusetyenzwa kwePP (polypropylene) iingxowa ezilukiweyo, irafi, ijumbo bags (FIBCs), kunye namanye amalaphu eplastiki afanayo. Ezi zixhobo zihlala zikhaphukhaphu, azikwazi ukukrazula, kwaye kunzima ukuzondla ngokuthe ngqo kwiinkqubo zepelletizing zemveli ngenxa yolwakhiwo olukhulu. Lo mgca udibanisa ukutyumza, ukudibanisa, ukukhupha, ukuhluza, kunye ne-pelletizing ibe yinkqubo eqhubekayo eguqula izinto ezisetyenzisiweyo zeplastiki ezilukiweyo kwiipelisi zeplastiki ezifanayo.

Esi sisombululo sifanelekile ekusetyenzisweni ngokutsha kwenkunkuma yokupakisha yasemva kwamashishini nasemva kwabathengi, inceda ekunciphiseni ukungcoliseka kwendalo kunye nokuhlaziya imathiriyeli ekrwada kwishishini leplastiki.

Iingenelo

Inkqubo eDityanisiweyo yeCompactor: Icinezela ngokufanelekileyo izinto ezilula, ezilukiweyo zokuqinisekisa ukondla okugudileyo kwaye okuzinzileyo kwi-extruder.

Ukusebenza okuphezulu: Yenzelwe ukusetyenzwa komthamo ophezulu kunye nokusebenza ngokuqhubekayo kunye neemfuno eziphantsi zabasebenzi.

Imveliso ehlala ixesha elide kunye neZinzile: Ivelisa iipellet ezifanayo ezineempawu ezilungileyo zomatshini, ezifanelekileyo ukuphinda zisetyenziswe emazantsi omlambo.

Iphatha iMathiriyeli enguMceli mngeni: Yakhelwe ngokukodwa ukuphatha iibhegi ezilukiweyo, iibhegi zejumbo ezineliner, kunye nenkunkuma yeraffia.

Uyilo oluSetyenziswayo: Ulungelelaniswa ngeendlela ezahlukeneyo zokusika, ukukhupha, kunye nokucoca ezilungiselelwe iimeko ezahlukeneyo zemathiriyeli.

Iingxaki

Unyango lwangaphambili lusoloko lufuneka: Iingxowa ezilukiweyo ezimdaka zisenokufuna ukuhlanjwa nokomiswa phambi kokuba zisetyenziswe ngokutsha ukugcina umgangatho wepellet.

Ukusetyenziswa kwamandla aphezulu: Ngenxa yokudibanisa kunye nokunyibilika kwezinto ezixineneyo, inkqubo inokusebenzisa amandla amaninzi.

Uvakalelo lweMathiriyeli: Ubukhulu bezinto ezingahambelaniyo okanye imisonto yokuthunga eshiyekileyo inokuchaphazela ukondla kunye nokuzinza kwe-extrusion.

Usetyenziso

Ukurisayikilishwa kweengxowa ezilukiweyo zePP: Zilungele iingxowa zesamente, iingxowa zerayisi, iingxowa zeswekile, kunye neengxowa zesondlo sezilwanyana.

IJumbo Bag (FIBC) Ukusetyenzwa kwakhona: Isisombululo esisebenzayo sokurisayikilisha izikhongozeli ezinkulu ezithambileyo eziphakathi.

Ukwenziwa kwakhona kweNkunkuma yoMqhaphu kunye neRaffia: Ilungele abavelisi bempahla elukiweyo elukiweyo kunye neemveliso zerafi ukuze baphinde basebenzise i-edge trim kunye nenkunkuma.

Imveliso yePlastiki yePellet: Ivelisa iigranule zePP ezikumgangatho ophezulu ukuze ziphinde zisetyenziswe kwi-injection yokubumba, i-extrusion, okanye ukuvuthela ifilimu.

4.EPS/XPS Granulation Line

I-EPS/XPS Granulation Line yinkqubo ekhethekileyo yokurisayikilisha eyenzelwe ukusetyenzwa kwepolystyrene eyandisiweyo (EPS) kunye nenkunkuma ekhutshiweyo yepolystyrene (XPS) yogwebu kwiigranule zeplastiki ezinokuphinda zisetyenziswe. I-EPS kunye ne-XPS zikhaphukhaphu, izinto ezinogwebu ezidla ngokusetyenziswa xa kupakishwa, kugqunyelelwe, nasekwakheni. Ngenxa yobuninzi bendalo kunye noxinaniso oluphantsi, kunzima ukuphatha kusetyenziswa izixhobo zeplastiki eziqhelekileyo zokurisayikilisha. Lo mgca wegranulation ngokuqhelekileyo uquka ukutyumza, ukudibanisa (ukunyibilika okanye ukuxinana), ukukhupha, ukuhluza, kunye neenkqubo zokudibanisa.

Injongo ephambili yalo mgca kukunciphisa umthamo, ukunyibilika, kunye nokuphinda kusetyenziswe inkunkuma ye-EPS / XPS ye-foam kwiipellets ezifanayo ze-polystyrene (GPPS okanye i-HIPS), enokusetyenziswa kwakhona kwimveliso yeplastiki.

Iingenelo

UkuNcitshiswa koMqulu: I-compactor okanye inkqubo yoxinaniso inciphisa kakhulu umthamo wezinto zogwebu, iphucula ukusebenza kakuhle kokutya.

Isiphumo esiPhezulu esineZibonelelo zokuKhanya: Yenzelwe ngokukodwa i-foam ephantsi, iqinisekisa ukondla okuzinzile kunye nokugqithisa okuqhubekayo.

Uyilo lweScrew Lokonga Amandla: I-Screw ephuculweyo kunye nesakhiwo sombhobho siqinisekisa ukunyibilika okusebenzayo kunye nokunciphisa ukusetyenziswa kwamandla.

Ihambelana nokusiNgqongileyo: Inceda ekunciphiseni inkunkuma yokulahla inkunkuma kwaye ixhasa ukusetyenziswa kwesetyhula yokupakishwa kogwebu kunye nemathiriyeli yokugquma.

Imveliso enokuphinda isetyenziswe: Iigranuli eziveliswayo zifanelekile ukuba ziphinde zisetyenziswe kwizinto ezingezizo ukutya ezifana namaphepha okugquma okanye iiprofayili zeplastiki.

Iingxaki

Ifuna i-Foam ecocekileyo neyomileyo: I-EPS / XPS kufuneka ikhululeke kwioli, ukutya, okanye ukungcoliswa okukhulu ukugcina umgangatho we-pellet.

Ivumba kunye noLawulo loMsi luyafuneka: Ukunyibilika kwegwebu kunokukhupha umsi; Ukungena komoya okufanelekileyo okanye iinkqubo zokukhupha umoya zibalulekile.

Ayifanelekanga kwiMixed Plastics: Inkqubo ilungiselelwe i-EPS / XPS ecocekileyo; izinto ezixutyiweyo zinokuvala okanye zithobe umgangatho wemveliso.

Usetyenziso

UkuPakisha ukuSebenzisa kwakhona kwegwebu: Kukulungele ukusetyenzwa ngokutsha kwepakethe ye-EPS emhlophe esetyenziswa kwizinto zombane, izixhobo zombane, kunye nefenitshala.

UBuyiselo lweMathiriyeli yoKwakha: Ifanelekile i-XPS yebhodi ye-scrap ukusuka kwi-insulation yokwakha kunye neepaneli zodonga.

Ulawulo lweNkunkuma yeFactory Foam: Isetyenziswa ngabavelisi bemveliso ye-EPS/XPS ukuphinda kusetyenziswe imiphetho yemveliso kunye neziqwenga ezikhatywayo.

I-Polystyrene Pellet Production: Iguqula inkunkuma yogwebu ibe yi-GPPS/HIPS granules ukwenzela izicelo ezisezantsi ezifana namaphepha eplastiki, ii-hangers, okanye iimveliso ezibunjiweyo.

5. I-Parallel Twin Screw Granulation Line

I-Parallel Twin Screw Granulation Line yinkqubo yokusetyenzwa kweplastiki esebenzisa izikrufu ezibini ezinxuseneyo zokunyibilika ukunyibilika, ukuxuba, kunye nepelletize imathiriyeli eyahlukeneyo yeplastiki. Xa kuthelekiswa ne-screw extruders enye, izikrufu ezingamawele zibonelela ngokuxutywa ngcono, imveliso ephezulu, kunye nolawulo olukhulu kwiimeko zokusetyenzwa. Le nkqubo ilungele ukurisayikilisha iiplastiki ezixubeneyo, ukudibanisa izongezo, kunye nokuvelisa iigranule zeplastiki ezikumgangatho ophezulu ezineempawu eziphuculweyo.

Umgca ngokubanzi uquka inkqubo yokutya, i-parallel twin screw extruder, iyunithi yokucoca, i-pelletizer, kunye necandelo lokupholisa / ukomisa, eyenzelwe umsebenzi oqhubekayo kunye nozinzile.

Iingenelo

Ukuxuba okuPhakamileyo kunye nokuDibana: Izikrufu zamawele zibonelela nge-homogenization egqwesileyo, evumela ukudityaniswa kweepolymers ezahlukeneyo kunye nezongezo.

Ukuphumelela okuphezulu kunye nokusebenza kakuhle: Ibonelela ngemveliso ephezulu kunye nokuzinza okungcono kokusebenza xa kuthelekiswa ne-screw extruders enye.

UkuPhathwa kwezinto eziNyenyeneyo: Kufanelekile ukusetyenzwa koluhlu olubanzi lweeplastiki, kubandakanywa i-PVC, i-PE, i-PP, i-ABS, kunye neeplastiki ezixutywe ngokutsha.

Ulawulo lweNkqubo eYomeleziweyo: Isantya esizimeleyo se-screw kunye neendawo zobushushu zivumela uhlengahlengiso oluchanekileyo lomgangatho wepellet.

I-Degassing ephuculweyo: Ukususwa ngokufanelekileyo komswakama kunye nokuguquguquka, okukhokelela kwiipellets ezicocekileyo.

Iingxaki

Utyalo-mali oluPhezulu oluPhezulu: Iinkqubo ze-twin screw zidla ngokubiza kakhulu ukuzithenga nokugcina kunezikrufu zesikrufu esinye.

Ukusebenza okuntsonkothileyo kunye noLondolozo: Ifuna abasebenzi abanezakhono kunye nokugcinwa rhoqo ukugcina izikrufu kunye nemigqomo ikwimeko entle.

Ayilunganga kwiMathiriyeli yeViscosity ephezulu kakhulu: Ezinye izinto ezibonakalayo ezibonakalayo zinokufuna izixhobo ezikhethekileyo okanye iimeko zokusetyenzwa.

Usetyenziso

IPlastiki iRecycling: Iyasebenza ekulungiseni kwakhona inkunkuma exutyiweyo yeplastiki ibe yigranule efanayo ukuze iphinde isetyenziswe.

Ukudityaniswa kunye neMveliso ye-Masterbatch: Isetyenziswe ngokubanzi ekuveliseni iikhompawundi zeplastiki ezinezihluzi, ii-colorants, okanye izongezo.

I-PVC kunye ne-Engineering Plastics Processing: Ilungele ukuphatha iipolymers ezinobushushu kunye nobunzima.

Ukwenziwa kweMathiriyeli eSebenza ngokuPhezulu: Isetyenziselwa ukuvelisa iiplastiki ezikhethekileyo ezinomatshini okanye iikhemikhali ezilungelelanisiweyo.

Amanqaku aphambili okukhetha eyona ilungileyo IPlastiki yokuRecycling yoMshini weGranulation Type

Oku kulandelayo yingqwalasela ebalulekileyo yokukhethwa koMatshini wePlastiki wokuRecycling iGranulation onokuzalisekisa iimfuno zakho zokwenziwa.

1. Yazi Uhlobo Lwakho Lwezinto

IiPlastiki ezithambileyo (umzekelo, ifilim, iingxowa, ugwebu): Khetha umatshini onecontractor okanye i-densifier ukuqinisekisa ukutya okugudileyo.

Iiplastiki eziqinileyo (umzekelo, iibhotile, izikhongozeli eziqinileyo): Umgca wegranulation otyumkileyo onokutya okuzinzileyo ufanelekile ngakumbi.

IiPlastiki ezixutyiweyo okanye ezosulelekileyo: Qwalasela i-twin screw extruders ngokuxuba okunamandla kunye nokukwazi ukuhluza.

2. Vavanya iiMfuno zoMxholo weZiphumo

Qikelela umthamo wakho wemihla ngemihla okanye ngenyanga.

Khetha imodeli ehambelana nomthamo owufunayo (kg/h okanye iitoni/ngosuku) ukuthintela ngaphantsi okanye ubungakanani obugqithisileyo.

Ukuhlaziywa kwezinto ezinkulu, i-high-output-screw-screw okanye iinkqubo eziphindwe kabini zifanelekile.

3. Qwalasela uKutyisa & IiMfuno zoNyango lwangaphambili

Ngaba imathiriyeli yakho ifuna ukuhlanjwa, ukomiswa, okanye ukucolwa ngaphambi kokuba igranulation ihlanjwe?

Abanye oomatshini babandakanya ii-shredders ezidibeneyo, iiwasha, okanye ii-compactors. Abanye bafuna izixhobo zangaphandle.

Izinto ezingcolileyo okanye ezimanzi zifuna iinkqubo eziqinileyo ze-degas kunye nokucoca ukunyibilika.

4. Qwalasela uMgangatho wePellet yokuGqibela

Ukusetyenziswa komgangatho ophezulu (umzekelo ukuvuthela ifilimu, ukubumba inaliti), ubukhulu bepellet obungaguqukiyo kunye nomba wobunyulu.

Oomatshini abanolawulo oluchanekileyo lobushushu kunye nokutshintsha isikrini okuzenzekelayo bavelisa isicoci, iigranuli ezifanayo.

5. Ukusebenza kakuhle kwamandla kunye nokuzenzekelayo

Jonga oomatshini abaneemotor ezilawulwa yi-inverter, izifudumezi ezonga amandla, kunye ne-PLC automation.

Iinkqubo ezizenzekelayo zinciphisa iindleko zabasebenzi kwaye ziqinisekisa umgangatho wemveliso ongaguqukiyo.

6. ULondolozo kunye neNkxaso yeeNdawo eziSetyenzisiweyo

Khetha umatshini kumthengisi othembekileyo onenkonzo yokuphendula ngokukhawuleza, inkxaso yobugcisa, kunye neendawo ezisetyenziswayo ezifikeleleka lula.

Uyilo olulula lunokunciphisa ixesha lokuphumla kunye nokunciphisa iindleko zokulondolozwa kwexesha elide.

7. Ukwenza ngokwezifiso kunye noKwandiswa kwekamva

Qwalasela oomatshini abanoyilo lwemodyuli oluvumela uhlaziyo (umzekelo, ukongeza i-extruder yesibini okanye ukutshintsha uhlobo lwepelletizing).

Inkqubo ebhetyebhetye iqhelana neentlobo zemathiriyeli entsha okanye iziphumo eziphezulu njengoko ishishini lakho likhula.

Qwalasela OMSHISHINI WUHE's iPlastiki Recycling iNkonzo yeGranulation Machine

Njengomvelisi oqeqeshiweyo onamava angaphezu kwama-20 eminyaka, I-WUHE MACHINERY (i-Zhangjiagang Wuhe Machinery Co., Ltd.) iyagqwesa kuyilo, imveliso, kunye nenkonzo yehlabathi jikelele yoomatshini bokuhlaziywa kweplastiki.

Ngaphezulu kweenkqubo ze-500 ezifakwe kunye ne-1 yezigidi zeetoni zeplastiki ezicutshungulwayo ngonyaka-ukunciphisa uqikelelo lweetoni ze-360,000 ze-CO₂ emissions-WUHE ibonakalise amandla ayo obugcisa kunye nefuthe lokusingqongileyo.

Ixhaswa yi-ISO 9001 kunye nezatifikethi ze-CE, zibonelela ngezisombululo ezidibeneyo zefilimu, ibhegi elukiweyo, i-EPS/XPS, iplastiki etyumkileyo, kunye nemigca yegranulation engamawele amabini. Ulawulo lwabo olungqongqo lomgangatho, uyilo lwemodyuli yenkqubo, ukuba bhetyebhetye kwe-OEM/ODM, kunye nenkxaso ephendulayo emva kokuthengisa iqinisekisa ukuba abathengi be-B2B bafumana izisombululo ezithembekileyo, ezisebenza kakuhle, nezilungiselelwe ukurisayikilisha kwihlabathi jikelele.

Khetha i-WUHE MACHINERY ngokusebenza okuthembekileyo, izisombululo ezilungiselelwe ngokutsha, kunye neqabane elithembekileyo ekwakheni imboni yeplastiki eluhlaza, ezinzileyo.

Ixesha lokuposa: Jul-01-2025